As I mentioned in my previous article, EARTH University graduates are steadily promoting EM technology in Central and South America. In Belize, the activities are also progressing well. Here I’d like to introduce an example of wastewater treatment at a sugar mill, where purifying the water is a very difficult task.

Sugar refinery wastewater contains massive amounts of butyric acid bacteria, which constantly causes concentrated contamination, rendering conventional wastewater purification technologies completely ineffective. Instead, sugar mills numerous ponds are constructed to conduct long term natural purification of wastewater, which takes years.

This process, however, can produce foul odors, which can be detected several kilometers away. This in turn cause various sanitation issues and ecological destruction, including health problems and downstream pollution.

EM is now able to solve all of these problems and has expanded to countries such as Brazil, Argentina, and Colombia.

Belize Sugar Industries Limited (BSI) is Belize’s leading sugar producer, established in 1963 and manufacturing sugar products since 1967. Operating the only sugar mill in northern Belize, it produces plantation white sugar, brown sugar, and molasses. Its annual sugarcane crushing capacity is approximately 1.3 million tons, sourcing raw materials from over 5,000 independent farmers nationwide.

Furthermore, the company generates renewable energy using a cogeneration system fueled by bagasse, sugarcane residue, which it uses internally and also supplies to the national power grid (equivalent to approximately 15% of the country’s total demand). It is a platform company that supports regional agriculture and energy.

One of the biggest concerns in sugar refineries is the wastewater generated during the sugar manufacturing process. Such wastewater contains large amounts of organic matter such as sugars and fibers, and when the balance of decomposition is disrupted, this wastewater produces a strong foul odor and turbidity.

BSI also experienced issues with odors from hydrogen sulfide and ammonia in the wastewater treatment ponds, which led to concerns about their impact on aquatic life and fish in nearby rivers.

Additionally, the wastewater had issues with its quality indicators, COD and BOD.

BOD and COD are indicators of water pollution. COD stands for Chemical Oxygen Demand.

It measures the amount of oxygen required to chemically decompose pollutants in water using chemicals. BOD stands for Biochemical Oxygen Demand. It is a measure of the amount of oxygen consumed by microorganisms when decomposing pollutants in water. The higher the numbers for both, the more polluted the water is.

Activated EM tank

The solution chosen was EM, which makes use of the power of microorganisms. This practical approach simultaneously tackles odor, water quality, and cost.

At BSI, they produce activated EM solution on-site, which was then introduced into the wastewater system once a week. This approach involves designing the input points and frequency, employing existing equipment but switching operational methods. This shifted the primary decomposition process from putrefaction to fermentation, aiming to address the source of odors and improve water quality at the same time.

One year after introducing EM, odors were controlled, flies were reduced, and water quality indicators (COD/BOD) improved.

In addition, reducing blower maintenance costs through aeration also led to lower labor expenses for managing the wastewater treatment pond, significantly reducing overall costs.

Aeration is a method of introducing fine air bubbles into water, supplying oxygen while using the buoyancy of the bubbles to agitate the water. It is widely used in water purification plants and sewage treatment facilities.

Typically used to aid the activity of aerobic microorganisms in the water, BSI employs aeration for agitating wastewater. This method has proven highly effective for the wastewater ponds, and combined with the suppression of putrefaction brought about by EM, has helped reduce electricity consumption.

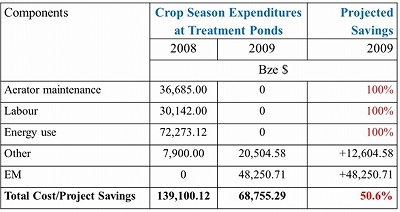

As shown in the “Cost Management Comparison Table (Currency: Belize Dollar) below, the entire project has seen a reduction of approximately 50.6%.

[Wastewater Cost Comparison (BSI)]

*Currency: Belize Dollar (Bze $)

Yen conversion is approximate. Calculated at 1 BZD = 75 yen (Belize dollar pegged to US dollar at 2 BZD = 1 USD). The Yen conversion amounts vary depending on fluctuations in the USD/JPY exchange rate. Fractions are rounded.

(Source: “Outstanding Cost Reduction in Waste Water Treatment”/ EM GROUP JAPAN)

Read the original Japanese message at the link below.

2025.11.1 Updated.