The goal of Kitanakagusuku Village Biomass Recycling Center in Okinawa Japan is to reactivate agriculture while reducing plant residues, aiming to convert them into high-quality resources with EM technology.

In 2013, Kitanakagusuku village in Okinawa Japan established the “Kitanakagusuku Village Biomass Recycling Center” for reducing plant residue. In July 2020, Kitanakagusuku village appointed EMRO as the designated manager. In order to convert plant residue into resources, they are composted, carbonized using EM technology. In addition, Kitanakagusuku village has contributed with Activated EM・1 to the local inhabitants via the municipality for over 10 years ago.

The manpower is usually 2 people. There are two methods of collecting plant residue. The staff visit requested homes to collect plant residue once a week or those who wish to dispose of it can bring it in person.

After collecting plant residue from requested houses

Plant residue brought by residents

After the sorting

Branches less than 10cm in diameter are crushed by a wood chipper

Applying Activated EM・1 to wood chips once every 10 days

1. Wood chips, rice bran and chicken manure are mixed

2. EM fermented Awamori waste liquid is added and stirred in

3. Fermentation in composted bark (After stirring, the temperature increases up to 60-70℃)

4. After the temperature decreases, it is stirred more

5. Accumulation and maturation

6. The composted bark is packed in 20L bags

Weeds and Leaves that are difficultly crushed by machine are applied Activated EM・1 and rice bran directly as pictured below for reduction to the farm.

Applying rice bran

Applying Activated EM・1

Stirring with heavy equipment

Application of humus in the banana farm

Carbonization of pruned branches using smokeless carbonizers that shut off oxygen and burn them

Non-application of mulch

Applying mulch

Walking areas in greenhouses

・Weed control and cost reduction

・Prevention of mud spatter as a cause of agricultural diseases

・Retaining Soil Moisture

・After cultivation, you can mix it with soil and it will enrich soils year after year

This is applied at Kitanakagusuku village primary school in flower pots and vegetable gardens.

Cherry trees in the village maintained by the local municipality

The garden of EM International Technical Center, located at Meio University in the Northern part of Okinawa

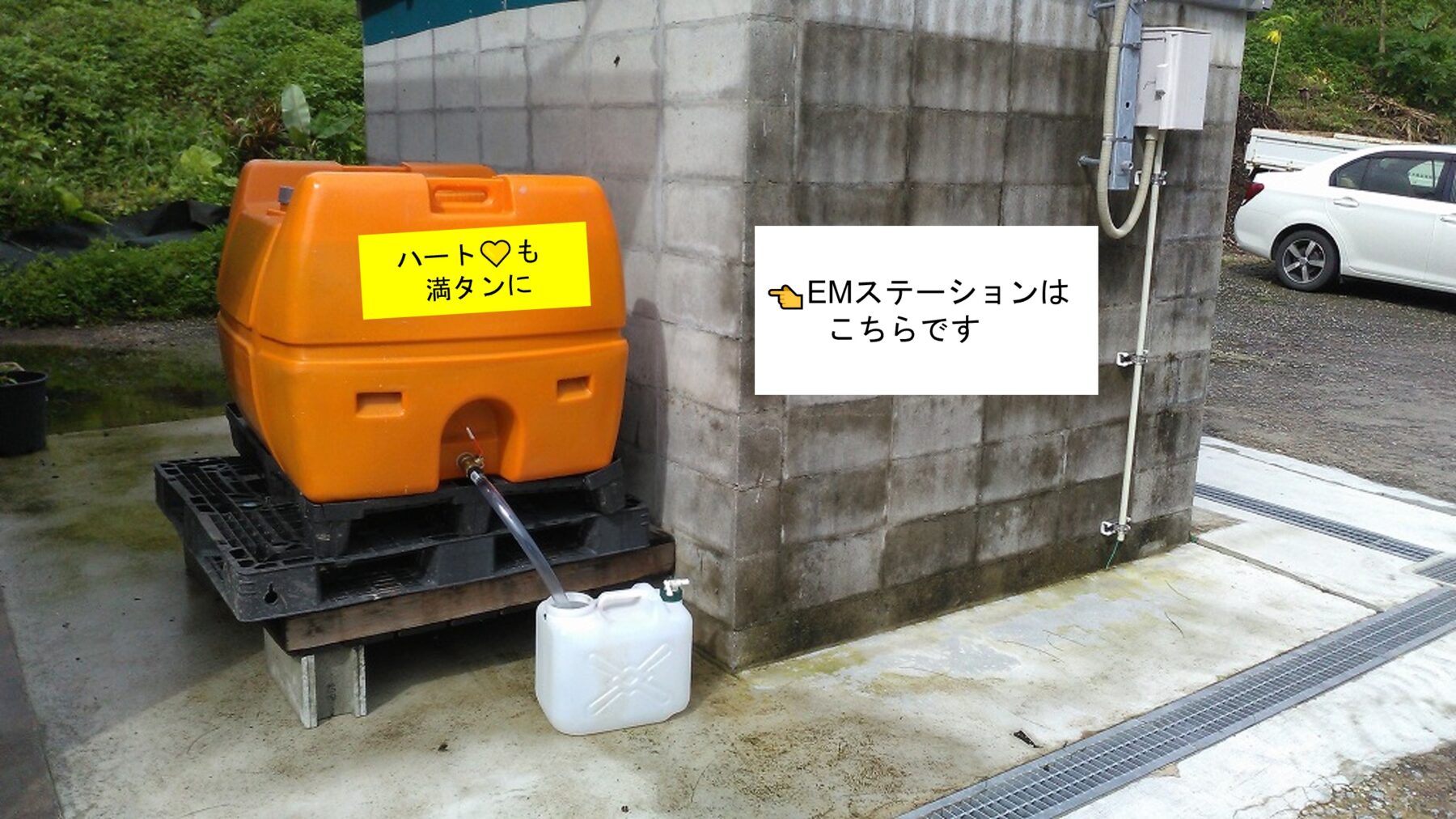

For more than 10 years, Activated EM・1 has been distributed to local residents via the municipality to contribute to their livelihood and promote environmental protection. The manufacturing and supply base has been managed at the biomass center since April 2022.

The goal is the revival of agriculture and the reduction of plant residues, aiming to convert them into high-quality resources with EM technology. What was once a waste product is now a valuable agricultural input.

2022.10.14 Updated