Ecuador was the first country in Latin America to successfully commercialize EM in fisheries field. Below is an overview of the current state of EM adoption in Ecuador.

In 1999, White Spot Disease (WSD) struck Ecuador’s shrimp industry, destroying approximately half of the country’s total shrimp production. EM helped overcome this crisis, and through its use many shrimp farmers were able to take the first step toward recovery.

The application of EM in the fisheries field in Latin America began in Ecuador and Colombia. In 1997, graduates of EARTH University started to promote EM, and they currently produces 5,000 liters of EM・1 per month.

Ecuador is the sixth largest shrimp producing country in the world and the largest in Latin America, and in the coastal area around the central city of Guayaquil, aquaculture is thriving, taking advantage of the delta region surrounded by lush mangroves and forests.

The full-scale introduction of EM began during the 1999 outbreak of WSD (White Spot Disease). As international regulations on antibiotics were tightened, Activated EM (AEM) gained notice as a key solution for disease control, and its effectiveness helped overcome the crisis. In aquaculture ponds, water quality management is critically important because shrimp larvae are raised in these ponds under anaerobic conditions, without oxygen supply equipment, and managing the health of baby shrimp and larvae determines the overall harvest yield. In recent years, a new disease caused by Vibrio bacteria known as EMS (Early Mortality Syndrome) has troubled aquaculture farmers worldwide. Conventional chemicals are not sufficient countermeasures, and a preventive approach utilizing EM has been growing in importance in Ecuador as well.

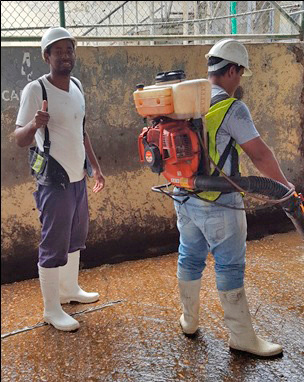

Ecuadorian shrimp farms utilize a production system that leverages the natural topography of mangroves, and is characterized by raising baby juvenile shrimp at lower densities compared to comparable production in Southeast Asia. The aquaculture ponds are 7 to 10 hectares in size, and their water management cycle follows this pattern: Water is drawn from the mangroves and stored in reservoirs. Utilizing elevation differences the water then flows into the aquaculture ponds. After harvesting, the used water is returned to the mangroves. Before releasing juvenile shrimp, organic matter and chicken manure fermented for two days using activated EM are added into the pond to promote plankton growth. This is a unique method at this farm, different from the traditional method of fermenting with bokashi. The farmers are confident that EM stabilizes water quality and enriches the pond’s plankton, leading to healthier shrimp growth, and they have been diligently applying this method in their daily work.

SOLE Farm, a certified organic plantation in north-central Ecuador, had long suffered damage to its bananas caused by nematodes that eat away at the roots of the plants. As they searched for an environmentally friendly method to overcome this problem without using nematicides, they began applying EM. In 2017, activated EM was mixed into irrigation water and applied to 350 seedlings over a two-month period, utilizing existing equipment. Afterwords, the soil in the plots where EM was applied was dug up and compared with that in the plots where it was not, revealing clearly visible differences.

In the EM treated area, numerous thick robust roots grew, weighing 127g. In contrast, the control area’s roots weighed a mere 34g, a threefold difference. Seedlings treated with EM displayed excellent growth, with virtually no observable nematode damage.

In the EM treated area, numerous thick robust roots grew, weighing 127g. In contrast, the control area’s roots weighed a mere 34g, a threefold difference. Seedlings treated with EM displayed excellent growth, with virtually no observable nematode damage.

Tanabe Farm, located in Concordia, Esmeraldas Province, Ecuador, cultivates their bananas using an environmentally and people-friendly method that combines natural cycle farming with EM technology. Their bananas are also exported to Japan, and you may have seen Tanabe Farm Brand bananas there at convenience stores and supermarkets.

Located at an altitude of approximately 300 meters, and blessed with a year-round warm climate, Tanabe Farm, spanning 320 hectares, minimizes the use of chemical fertilizers and pesticides instead utilizing activated EM and EM bokashi to produce high-quality bananas. After harvest, any bananas that do not meet their rigorous standards are shredded along with the stems and leaves and composed to feed earthworms. EM materials are also added to the vermicompost, and over the course of six months, this compost is transformed into rich organic fertilizer through the power of microorganisms and earthworms. This circular system enables sustainable agriculture with no waste.

Herbs are planted throughout the farm to control weeds, helping manage soil moisture without the use of herbicides. In addition, irrigation utilizes naturally sourced river water and ozonated well water, which is also employed in the washing process. Through such rigorous hygiene and quality control, the farm has also obtained Global G.A.P. (Good Agricultural Practices) certification. Tanabe Farm’s bananas continue to receive high praise even in Japan as “the banana of choice,” even if they are a little more expensive.

(Source: “EM-Grown Bananas / EM GROUP JAPAN”)

Click here for more information on implementation cases (EMRO website)

“I’m amazed at how much has changed in just five months. We used to receive frequent complaints from visitors about the strong odor, but now that’s completely gone. Instead, people now say it smells sweet, like bread or cookies. EM was the ideal choice we were looking for.” This clean, safe working environment achieved through EM is becoming increasingly widespread in other countries, serving as a good example for creating facilities that do not rely on chemicals and that coexist with the local community.

(Source: “No More Claims for Stench/ EM GROUP JAPAN”)

Click here for more information on implementation cases (EMRO website)

The above are representative examples from Ecuador. The Ecuadorian government is fully aware of the benefits of EM and is actively utilizing it to address environmental issues.

Read the original Japanese message at the link below.

2025.9.30 Updated.